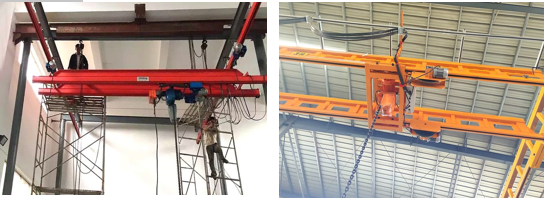

SINGLE GIRDER OVERHEAD CRANES

Capacity: Up to 20t, Span Length: Up to 31.5m

Applications: This crane is mainly used in steel stock yard, the concrete industry, warehouse, factory, harbor and ship building, etc. overhead crane a common feature of many industrial workplaces serving various lifting applications

Single girder overhead cranes are the most cost-effective purchase for capacity 20 tons and 18m span. Is usually classed as 3 types, LD type, low headroom type, LDP type. Single girder overhead crane is common lifting equipment which consists of single girder beam, monorail hoist, end carriage with motor and total panels. It can be installed on the steel columns. As it will be installed on the upper of the factory, have maximum space utilization.

Different types of Single Girder Overhead crane

LD Single Girder Overhead Crane

- Widely used for normal workshop.

- The main girder is U-type in the production process and fully finished one time, reduce the stress concentration point.

Cheap price with stable performance, reasonable structure, strong rigidity and durability

Low Headroom Type Overhead Crane

- Usually used for the workshop which upper space is limit, it’s can have higher lifting height, and it is more space-saving.

- Low headroom type electric hoist traversing below the main girder, but on both side of main girder.

- Lifting mechanism is equipped low headroom electric hoist, the structure is different. And more artistic.

LDP Type Single Girder Overhead Crane

- Usually used for the workshop whole height is limit, but customer want to reached a max lifting height.

- The main girder is box type. Low headroom type electric hoist traversing on the main girder.

- The hoist is on one side of the beamed, it can achieve higher lifting height.

DOUBLE GIRDER OVERHEAD CRANES

Capacity: up to 800t, Span Length: up to 37.5m

Application: Suitable for machining workshop, metallurgy industry workshop, warehouse, stockyard, power station, light and textile industry workshop, food industry workshop.

Double girder overhead crane is composed of main beam, cross traveling mechanism, long traveling mechanism, and electrical equipment. If you need to transport heavy loads more than 50t across large area of have high work duty, then double girder traveling cranes are you are your first choice.

Double girder overhead cranes can be fitted with maintenance platforms under motors, on the rigging or over the full span of the roller beam. It can be offered for a very large range of spans, heights of lift as well as customized speeds depending on your application. They can also be provided with multiple

hoisting trolleys running on the same bridge or auxiliary hoisting mechanisms on the main trolley.

QD Type Double Girder Overhead Crane

- Suitable for all kinds of working conditions, work duty can be divided A5 and A6.

- Used in mechanic processing workshop, metallurgical mills, warehouses, goods yard and power station.

- The entrance of cabin has three ways from side entrance, end entrance and top entrance.

LH Type Double Girder Overhead Crane

- It is mainly used in the general workshop, Lifting capacity: 5ton-32ton. working level A3-A4

- Application to workshop, warehouse, goods yard, power station, the work duty is less than QD type.

- The price is more cheap. Drive by electric: controlled by cabin and remote control.

WORKER STATION CRANE

Capacity: 125kg-2000kg, Span: 1.8-10m

Lift Height: up to 5m, Working Duty: A3-A5

Application: Used for flat materials conveying, and is suitable for workshop, warehouses, and other places

Monorail cranes are most effective in production applications where materials are repetitively moved from one point to another. The monorail hoist and trolley run on a single stationary beam, normally include H-beam or I-beam

High reliability and stability

Light crane system is composed of standard modular parts, which can guarantee mass and high quality production.

Strong adaptability

Light crane system can flexibly design and install according to the needs of each station in the factory. It can be assembled at will from fixed point to high accuracy multi-point and multi-beat automated transportation lines.

Convenient installation and economic efficiency

Standard module parts can be used only by bolt connection, which can save the factory floor space and improve enterprise benefits

Reduced plant cost, low power, low energy consumption and high comprehensive benefits.

EUROPEAN TYPE OVERHEAD CRANE

Capacity: up to 20t Span Length: up to 31.5m

Applications: Suitable for warehouse, material stocks and general factory site. They are especially suitable for material handling that requires precise positioning. Precision assembly of large parts and other occasions.

European type overhead crane is compact lifting machinery designed and manufacturing in strict accordance with FEM and DIN standard, which with advanced technology and beautiful design, and the driving mechanism adopts a three-in-one reducer (hard tooth surface reducer, frequency conversion brake motor), It equipped with low headroom hoists/trolley and variable frequency drives on both hoist and trolley.

Compare with other traditional crane, the limit distance between hook and wall is the minimum, the net height is lowest, can maximum the lift height, practically increase the efficient work space. Due to cranes’ light dead weight, and minimum wheel load, can largely reduce the workshop’s cost.

Advantages

Light dead weight, light wheel load, small boundary dimensions, dependable performance, ready operation.

Light wheel load and small boundary dimensions can reduce the costs of plant construction, save capital investment of lighting, heating and so on.

Using high-quality components can reduce failure rate and maintenance costs.

On the other hand, the total installed power (power consumption), low consumption of total power can reduce the costs.

mcorper mattis, pulvinar dapibus leo.

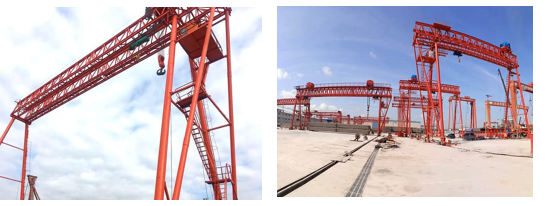

SINGLE GIRDER GANTRY CRANE

Capacity: Up to 50t Span Length: Up to 50m

Cantilever Length: 3m-8m Control Mode: Pendant control / Wireless remote control / Cabin control

Applications: High strength, good rigidity and high stability, low cost. Cover more work area, no need to build warehouse.

The gantry crane is not restricted by the workshop steel structure, and owing to the simple structure and convenient installation, used typically for activities in steel warehouse, precast yards, construction sites, port, train station, power plant and other outdoor applications.

The single girder gantry crane is mainly composed of steel structure gantry, crane traveling mechanism, electric hoist, and electric control system. Normally, single girder gantry cranes are most widely used and often in open storage yard.

Different Types of Single Girder Gantry Crane

A (MH) Type Single Girder Gantry Crane

- Suitable for indoor and outdoor, Strongbox type

- Crane can be designed with two side cantilever, one side cantilever or no cantilever.

L Type Single Girder Gantry Crane

- Crane leg is ‘L’ type, is it more convenience for large size goods from middle position move to cantilever without any dimensional limit of support leg.

- Crane can equip with two type lifting mechanism, one is steel wire rope hoist, the other one is trolley.

Truss Type Single Girder Gantry Crane

- Crane main girder and support leg both with truss type, it is more suitable for open area, can bear strong wind pressure.

- Crane can be design with full truss type or main girder with truss type, support with box girder or on the contrary.

DOUBLE GIRDER GANTRY CRANE

Capacity: Up to 800t Span Length: Up to 100m

Cantilever Length: 5m-15m Control Mode: Pendant control / Wireless remote control / Cabin control

Applications: High strength, good rigidity and high stability, low cost. Cover more work area, no need to build warehouse.

The double girder gantry crane is especially suitable for the heavy working frequency, and heavy used places, suitable for high work duty situation. It has the characteristics of compact structure, good manufacturability, flexible operation, strong carrying capacity, high site utilization, large operating range, wide adaptability, strong versatility, stable and reliable operation, etc.

Include single girder gantry crane, double girder gantry crane, semi gantry crane, trussed gantry crane. Suitable for indoor and outdoor usage.

Advantage: cover more work area, no need to build warehouse. Suit for both of outdoor and indoor.

Different Types of Double Girder Gantry Crane

Type Double Girder Gantry Crane

- Suitable for indoor and outdoor

- Gantry crane is designed for maximum flexibility and reduces structural and rail maintenance to a minimum.

Truss Type Double Girder Gantry Crane

- Crane main girder and support leg both with truss type, it is more suitable for open area, can bear strong wind pressure.

- Crane self-weight is lighter than the single girder gantry crane with box girder, also will reduce the cost.

U Type Double Girder Gantry Crane

- Crane design with U type, is it more convenience for large size goods from middle position move to cantilever without any dimensional limit of support leg, like gantry crane which used in the hydropower station with very large wheel gaug

TRUSSED GANTRY CRANE

Capacity: up to 200t Span Length: Up to 100m

Cantilever Length: 5m-15m Control Mode: Pendant control / Wireless remote control / Cabin control

Applications: Open yard. Used typically for activities in steel warehouse, precast yards, construction sites, port train station, power plant and other outdoor applications.

In general, Truss Gantry Crane Have three kinds of uses:

- First, Trussed Gantry Crane usually used in concrete beam yard, for lift beam girder which is used in bridge build.

- Second, Trussed Gantry Crane will use near to the bridge approach, for construct bridge approach after finished, engineer gantry crane also for lift concrete beam from ground transporter to bridge transporter, help launcher crane to build the whole bridge.

- Third, Engineer Gantry Crane is used for disassemble and re-erect launcher crane. Advantage: Trussed structure can bear large wind pressure, best choice for open yard. Compared with ordinary gantry cranes, installation and disassembly are convenient and quick, economical and practical.

Advantage: Trussed structure can bear large wind pressure, best choice for open yard. Compared with ordinary gantry cranes, installation and disassembly are convenient and quick, economical and practical.