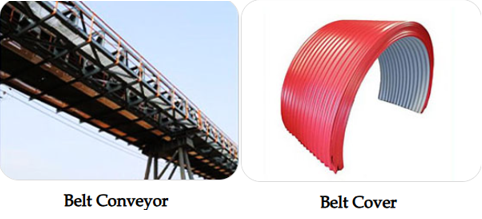

As contractors, we know that keeping operations running smoothly and efficiently is non-negotiable. That’s why we rely on high-quality idlers and pulleys—engineered for durability, performance, and minimal maintenance—to support the full load of a conveyor system. Whether it’s mining, chemical processing, or heavy industrial work, dependable components are critical to long-term success.

Built for the Real World

Our idlers play a crucial role in extending conveyor belt life by minimizing friction and ensuring reliable material flow. In addition to bearing the weight of conveyed materials, they maintain belt alignment, enabling smooth transport and clean discharge at the tail end.

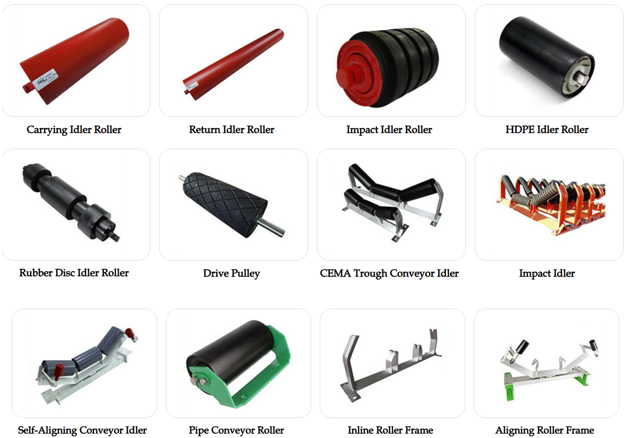

Our Idler & Pulley Lineup Includes:

🔹 Conveyor Idlers – Precision-engineered rollers offering stable belt support

🔹 Carrying Idlers – Reduce wear and extend belt life

🔹 Impact Idlers – Absorb shock in high-load areas and protect belt integrity

🔹 Return Idlers – Maintain belt tracking and assist in smooth return paths

🔹 Conveyor Pulleys – Designed for consistent belt movement and power transmission

🔹 Tail & Head Pulleys – Built to perform in tough, high-load environments

Added Value with Expanded Roller Options

Our conveyor roller range includes steel and HDPE carry and return rollers, along with rubber disc impact and return rollers—giving you options for every type of site condition. All rollers and frames are manufactured to a variety of standards or can be customized based on your jobsite requirements, incorporating innovative, maintenance-saving designs.

Every roller is fitted with deep groove ball bearings to deliver extended performance. With belt width options from 400 mm to 2000 mm, and larger sizes available on request, we’ve got the flexibility to meet your system’s demands. Under normal working conditions and proper maintenance, you can expect a roller lifespan of 30,000 to 50,000 hours—which means less downtime and more productivity.

Why Contractors Choose These Components:

✔ Heavy-Duty Durability – Built to handle the toughest jobsite demands

✔ Precision Engineering – Supports smooth, reliable conveyor movement

✔ Corrosion-Resistant – Ideal for rugged and harsh environments

✔ Custom-Built Solutions – Tailored to fit your conveyor specs with ease

When your reputation and schedule depend on reliable material handling, choosing the right idlers and pulleys isn’t just important—it’s essential.